Understanding Plastics Engineering and Blow Molding

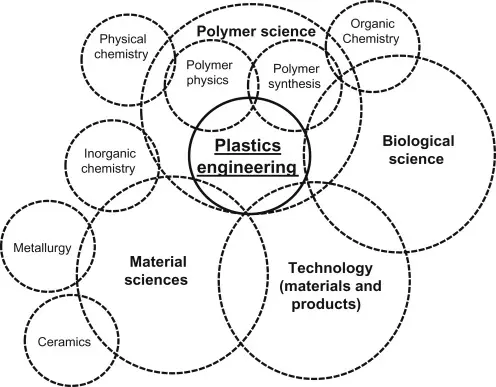

Our expert team of engineers is the industry leader in developing safe, innovative, and economical solutions to meet ever-changing market demands. We focus on our industry, contract blow molding. However, we also focus on all other plastics industries.